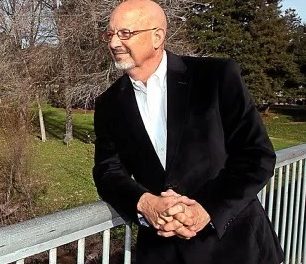

Photo Credit: Idea Fab Labs

This story first aired on Talk of the Bay. It is produced by Science Communications intern, Jesse Kathan.

Transcript

On the westside of Santa Cruz, the imposing Wrigley building has mostly gone dormant. Many tenants have had to close up shop amid the COVID-19 epidemic. One business is busier than ever.

[3D printing noises]

Layman: That’s a bad thing for the 3d printer. Hmm. Okay, well, we’re just gonna go with it

Jordan Layman is the founder of Idea Fab Labs, a d.i.y. workshop filled with laser cutters and 3d printers. Until recently, the makerspace held classes on everything from woodworking to jewelry making. But for the past four weeks, every employee and machine has been united in a single goal: making protective equipment for the county’s most vulnerable workers.

Earlier this month, the CDC issued a recommendation for anyone leaving their house to use a face covering. But disrupted supply chains and increased demand have created global shortages of medical-grade masks, leaving people scrambling to find alternatives. To help meet the need, Layman has partnered with Santa Cruz resident Catherine Sonquist Forest, a family physician with a Masters of Public Health.

[snippet of conversation Forest and Layman]

Forest also sits on the board of Encompass Community services, which runs several residential facilities for people with chronic mental illness and substance use disorders. After seeing coronavirus tear through nursing homes in Washington state, Forest became concerned about the safety of her patients, and their caretakers. She’d like to provide employees with n95 masks, the kind certified to filter out virus-bearing droplets. But worldwide shortages have left those masks scarce, even for medical professionals.

Forest: The distribution and availability of masks and cloth masks and surgical masks was so dire that many of our frontline physicians that were not part of large buying groups were going to be left out of the distribution and they were also very interested for themselves but also for the working people that they take care of: home health aides, farm workers, the people in our community that are in the interface for people whose work is important for the for society to function.

Forest helped Encompass join forces with local physicans’ groups to create Project PPE- that’s “Personal protective equipment.” Together, the group created a design for a four-layer cloth face mask that could offer protection to at-risk workers without access to medical-grade masks. Forest reached out to Jordan Layman at Idea Fab Labs to help fulfill the requests. Their usual business model of classes and workshops suspended, the Santa Cruz facility, and its sister site in Chico, eagerly pivoted towards large-scale production.

Layman: We’re the smallest form of fabrication facility. We don’t do more than 50 of something and usually we do three of something. So the idea of us producing thousands of something a day is something that’s usually left to another organization or facility. But the advantage that we have is that we’re very nimble. We can make quick decisions about those things, because we’re used to making all we’re used to making something completely different every time.

In a single day, the facility’s laser cutters can cut enough cloth for a thousand masks. The cut cloth is handed over to sewers that assemble the mask and add elastic headbands, producing close to three thousand masks in a week. Some sewers are paid by the fundraised money, while others volunteer their time. Over fifty people across the Central Coast have joined the effort — and their numbers are growing. The need is growing too.

Layman: Watsonville Hospital has hit us up, the city, the county. We’ve been in contact with so many different big organizations, as well as like, I think one of the sandwich shops hit us up today. So there’s a lot of need, and we’re definitely not able to supply all those people. But we’re really just starting to get going as far as production. Hopefully we’ll be able to get as many people protected as possible.

And masks aren’t the only thing they’re making.

[3d printing noises ]

Plastic face shields create another layer of protection for health care professionals caring for patients with COVID. With the help of 3-d printers, Layman’s team has made 450 face shields.

The county has also commissioned the construction of six plexiglass booths for people conducting swab tests. Forest and Layman hope to continue production until every person in need of protective gear has access.

Forest: This will be in our lives for the next, you know, year or two as the virus becomes endemic… We really need to figure out how to support and care for one another during this difficult time.

In Santa Cruz, with UC Santa Cruz’s Science Communications Program, this is Jesse Kathan, for KS